The wheel test device is used to simulate the behavior of corrosion inhibitors in pipes containing oil or chemical products. The Wheel test is a very economical way to check the corrosion rate and evaluate the corrosion inhibitors behavior. This test method provides the possibility of determining the corrosion rate with the minimum need for continuous monitoring of the operator and only by placing coupons at a certain time (several hours to several days).

Application: simulate the behavior of corrosion inhibitors in pipes containing oil or chemical products.

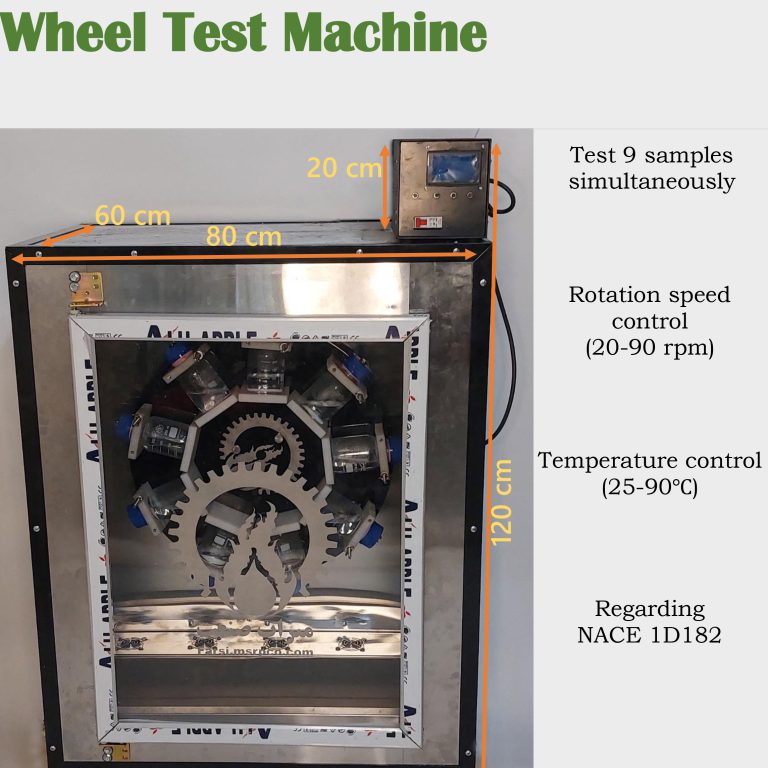

Standards: NACE 1D182

Technical specifications WT1880 are as follows:

- Ability to simultaneously check 9 to 18 different environments.

- Ability to increase the temperature uniformly inside the device up to 90°C.

- Ability to change the speed of rotation of the device between 20-90 rpm.

- Easy saintliness of the sample holders.

- Transparent door from Plexiglas to monitor the samples during the test.

- The inter and outer bodies of stainless steel.

- The possibility of planning the device in order to change their sample rotation in specified intervals.

- Ability to automatically disconnect the device after a specified number of rotations.