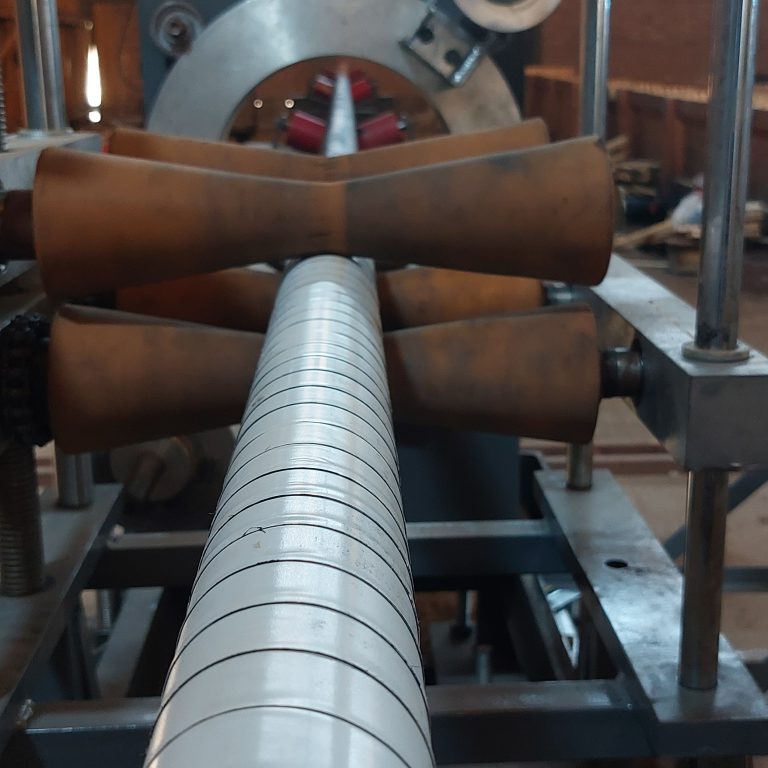

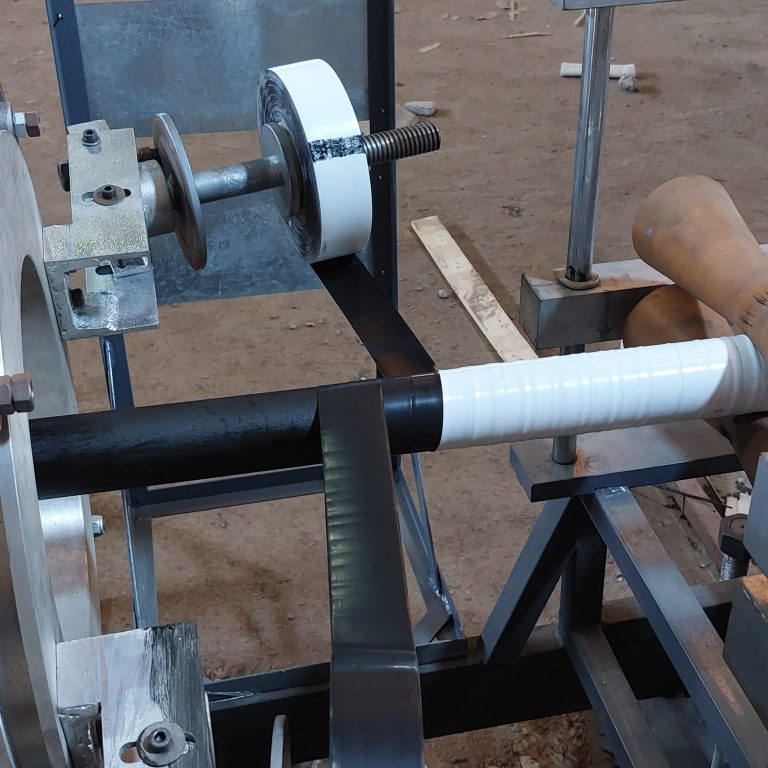

Automatic wrapping with a rolling system is used to wrap the pipes in sizes 2 inches and above. This device is designed for wrapping medium and large-size pipes and is installed permanently in the factory or workshop. This device has a roller system in the front and back and provides the possibility of wrapping 12-meter pipes in the size range of 2 inches and above with tapes of 2 and 4 inches wide.

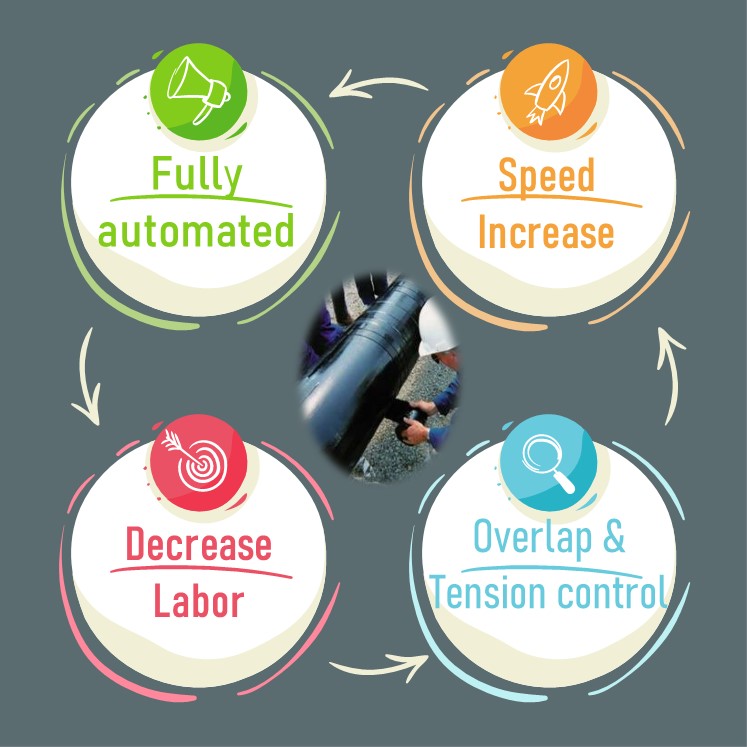

One of the most important advantages of this machine is the possibility of winding two tapes at the same time, the possibility of controlling the tension and overlap of the tape, complete continuity and uniformity of the tape, reducing manpower, and increasing the speed of tape wrapping up to ten times as compared with the manual mode.

The device has a feeding system, tape wrapping system, and tape tension control system. In order to automate the tape-wrapping process, two parallel systems of the motor, gearbox and inverter are used to control the speed of the tape-wrapping process.

Automatic wrapping with a rolling system is used for automatic tape wrapping of the pipe in order to apply tape on the pipe to reduce the corrosion rate of the pipe. In this device, tape loops are placed on the device in the desired places, then the settings of the device are applied to create the appropriate overlapping percentage. The advanced speed and tape tension are adjusted by the relevant systems and the device is turned on. In this method, tape wrapping is done completely automatically without the operator’s intervention.