In order to check the behavior and efficiency of the coatings in very corrosive conditions and harsh environments, the tests to check the properties of the coatings are used. These tests are designed to check the performance of the coating in working conditions and determine the resistance of the coating to environmental factors such as impact or scratches. The most important equipment for checking the performance of coatings manufactured by Mirab Sanat Inc. are as follows:

1-Scratch or gouge resistance test: This device is used to evaluate the scratch resistance of epoxy coatings such as single and triple-layer fusion-bonded epoxy (FBE) coatings and polymer coatings. In this method, the coated sample is placed in the device holder and its scratch resistance is calculated by the depth of the indentation created by the indenter. This machine is manufactured in accordance with NACE TM 0215 and CSA Z245.20 standards.

2-Cathodic disbonding test: In the conditions where cathodic protection is applied, the cathodic disbonding test is used to check the behavior of the coating during the application of cathodic protection.

3.Flexibility test: This test is designed to check the resistance to bending in three-layer coatings at different angles.

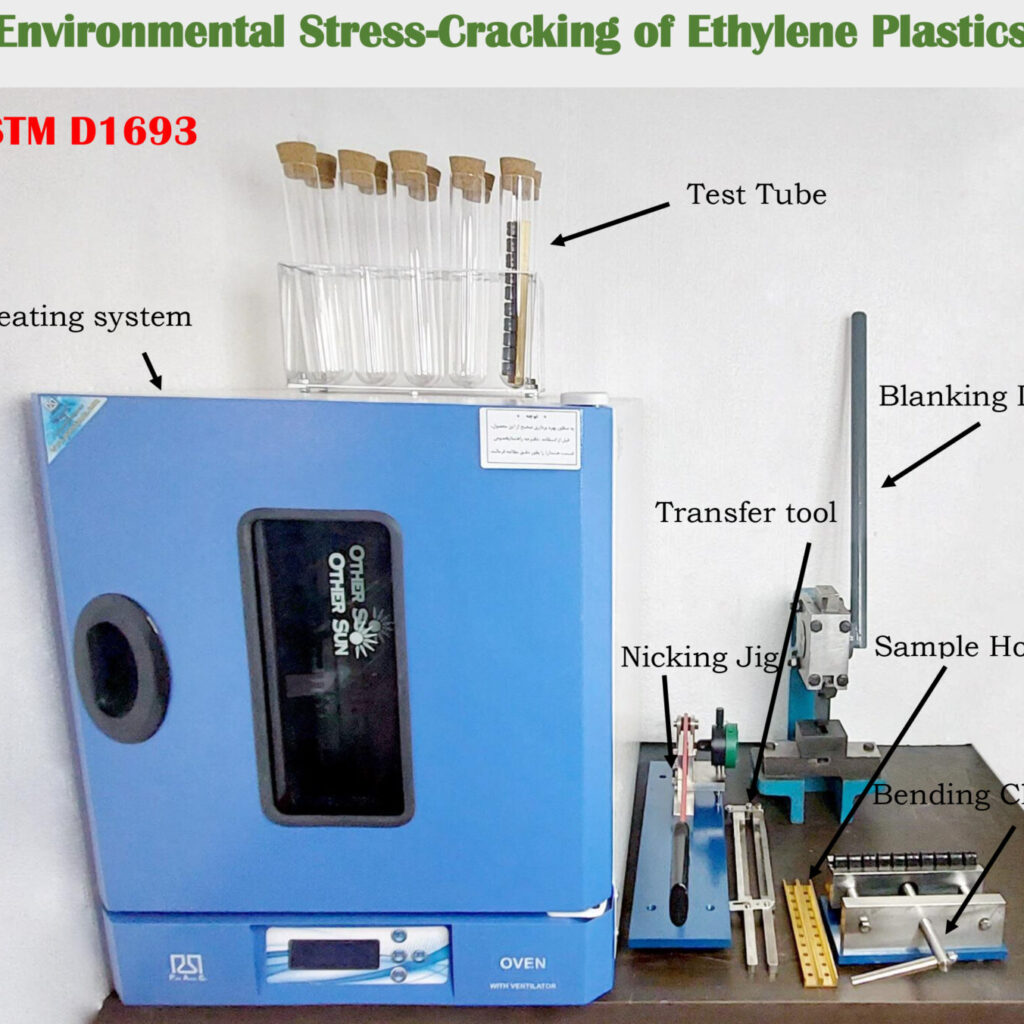

4.Environmental stress-cracking test of ethylene plastics (ESCR test) : is used to check the stability of ethylene plastics and coatings in the environment containing stress cracks and corrosive environment.

5.Indentaion test: It is designed as an accelerated test to check the resistance of the coatings on the pipe to the penetration of an external object, under constant temperature and loading conditions.

6-Impact resistance test: This device was designed and manufactured in order to check the impact resistance by drop weight method in accordance with ISO 21809-2 and ASTM D 2794 standards.

7-Hot press machine: This equipment is designed to produce sheets of adhesive granules and polyethylene granules for the purpose of producing sheets and making samples to perform standard tests 1 & 2 of ISO 21809 and provides the possibility of simultaneous control of pressure, temperature and time.