The copper corrosion test is designed to evaluate the relative corrosion rate of a petroleum product due to active sulfur compounds. The copper corrosion test is an oil analysis method for gearboxes, turbines, and hydraulic oils. This method shows the corrosion effects of lubricants, gasoline, lubricants, oil, LNG, and aromatic hydrocarbons on copper alloys regarding the ASTM D130, ASTM D849, and ASTM D1838 standards.

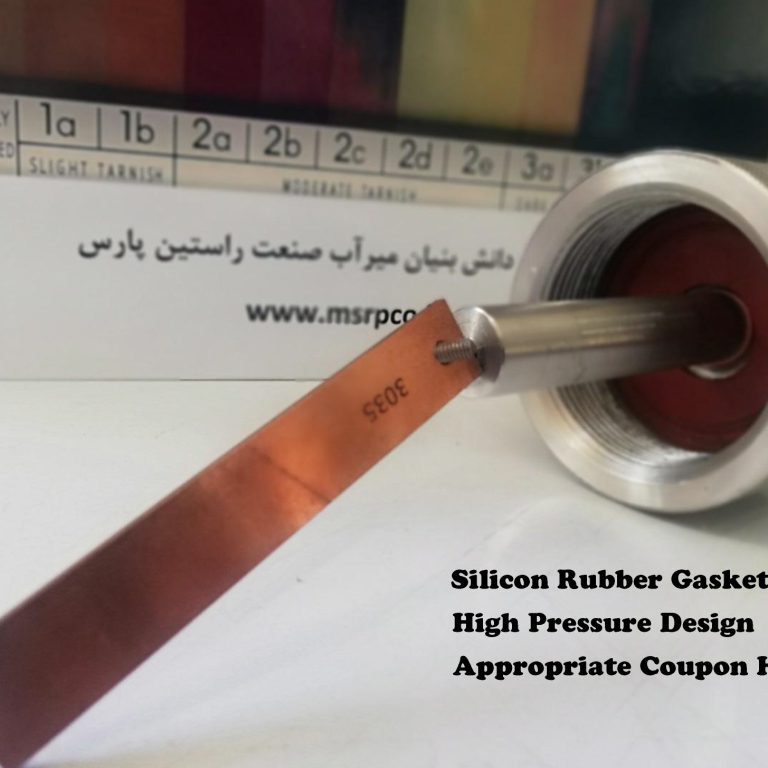

The method of analyzing copper corrosion oil is relatively simple. Polished copper corrosion test coupons are immersed in 30 ml of the sample at a high temperature (50 or 100 degrees Celsius) depending on the type of gasoline, oil, or oil tested for three hours. At the end of this period, the copper strip is checked for corrosion evaluation after cleaning. The results are evaluated by comparing the spots on the copper strip with the ASTM color scale from A1 to C4.