This device is designed to test the impact resistance of single-layer fusion-bonded epoxy (FBE) coatings in accordance with ISO 21809-2. In this method, a one-kilogram weight with a hardened tip of 8.15 mm in diameter is dropped on the sample from a height of one meter through a scaled weight guide.

The effect of the indented tip on the impact resistance of the coating is checked with the help of the Holiday test. It is worth noting that the device has a hardened floor according to the standard.

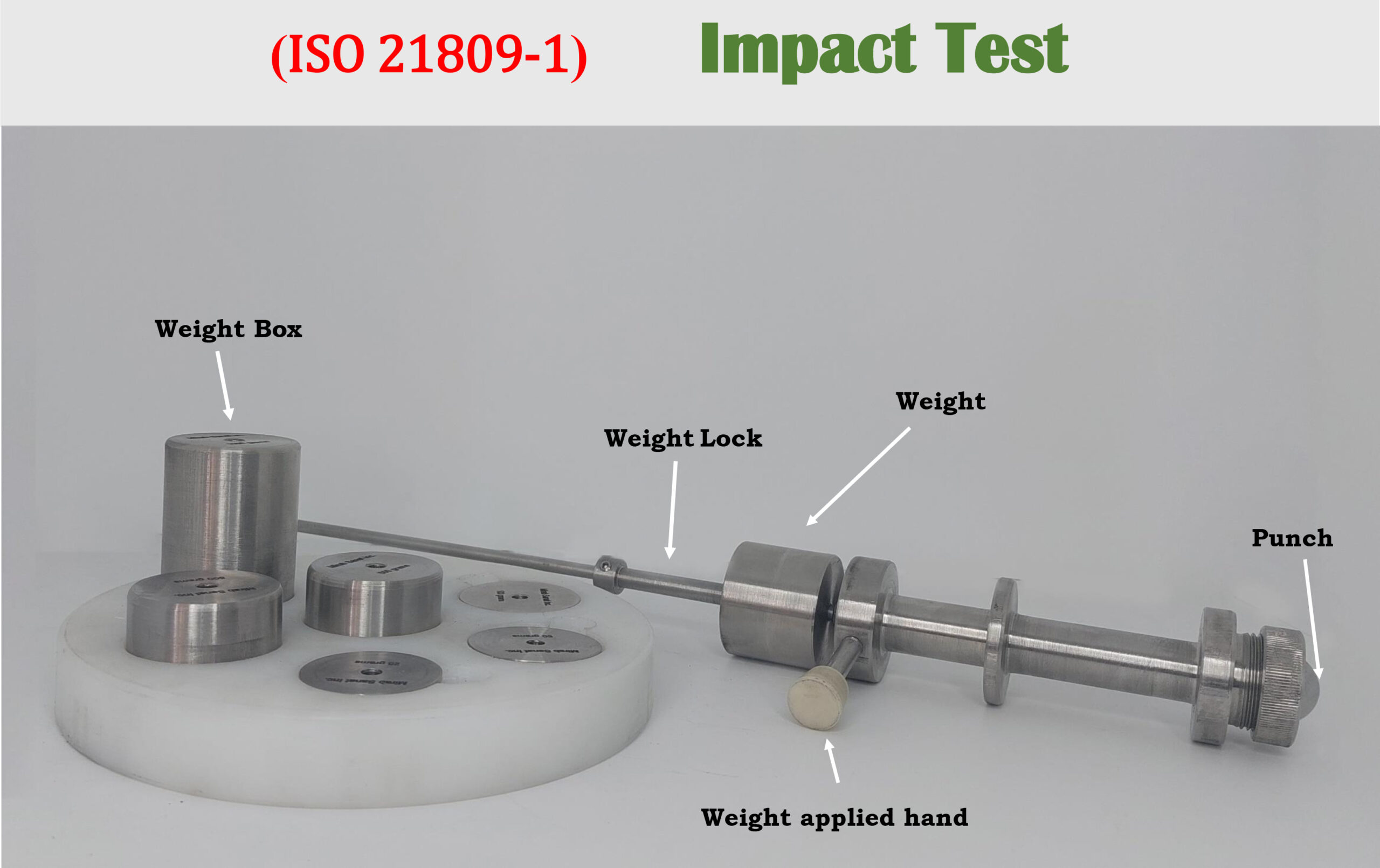

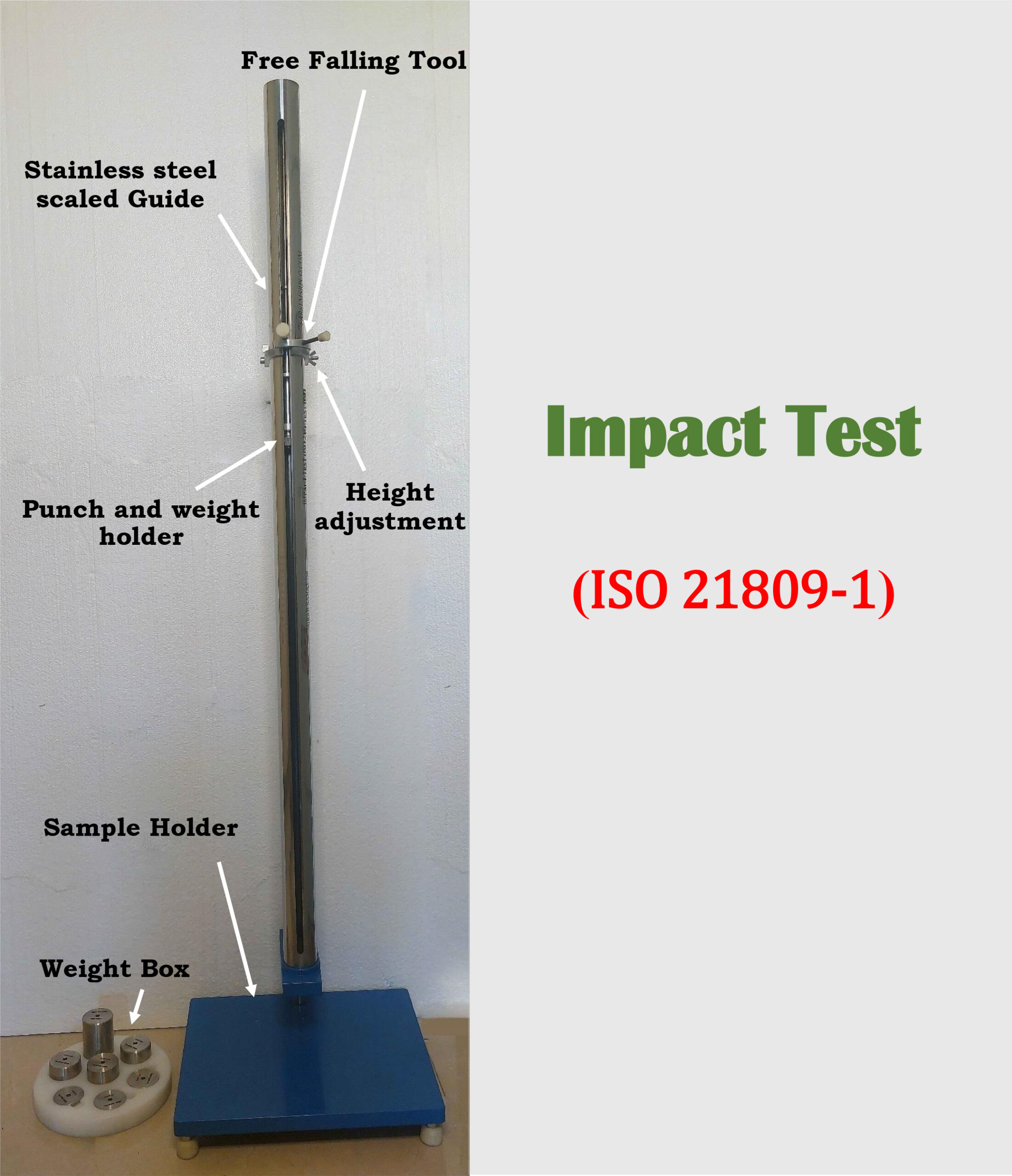

Drop weight / impact test

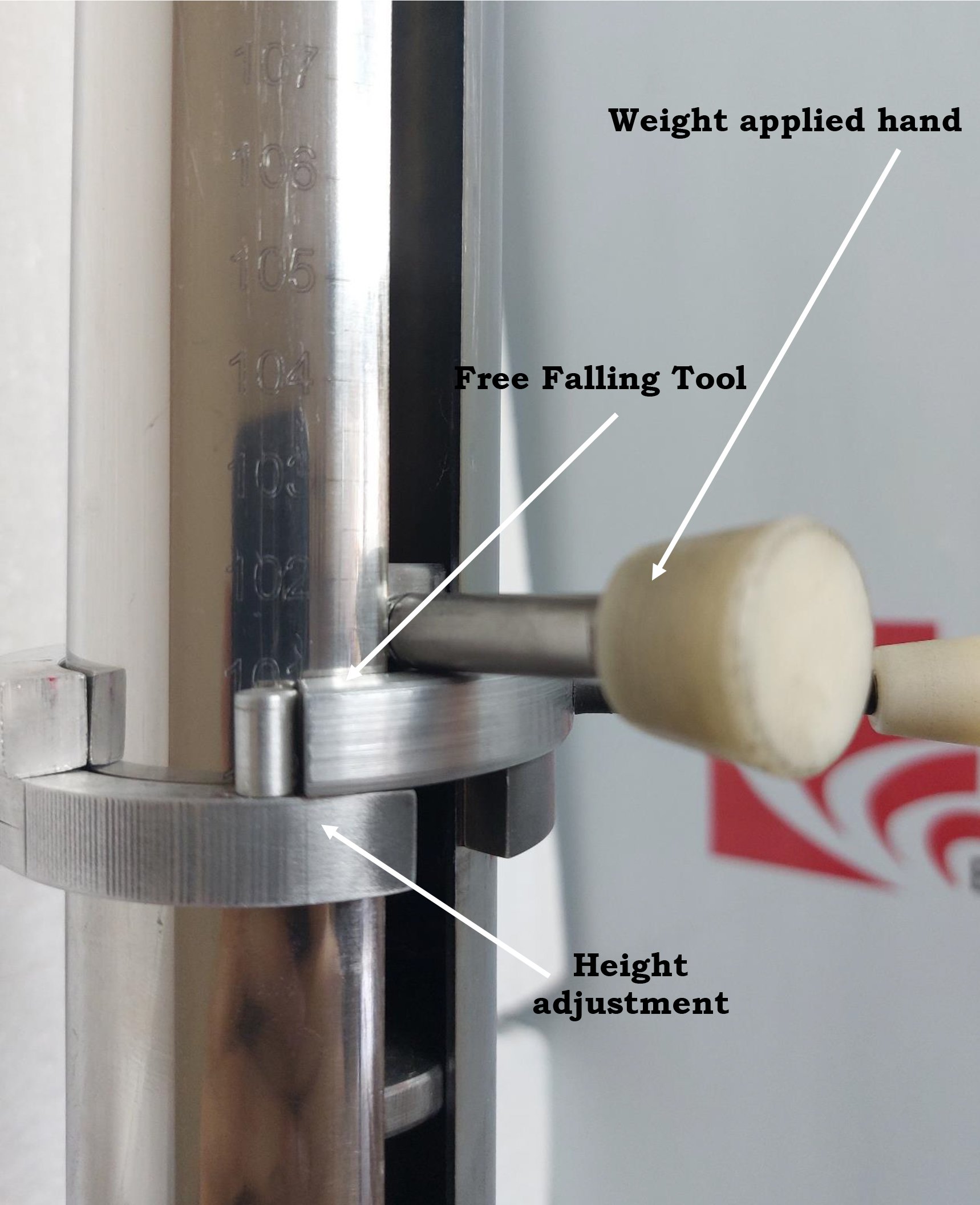

These devices are designed and manufactured in order to check and test impact resistance (quick deformation by impact) in organic coatings and single and three-layer fusion-bonded epoxy (FBE) coatings in accordance with ISO21809-2, ISO21809-1 and ASTM D 2794 standards. In this method, a one-kilogram weight with the weight specified in the standard is dropped from a specified height of one meter or variable (according to the standard) on the covered sample, and the special sinking effect of the test on the impact resistance of the coating with the help of the Holliday test and Visual inspection is checked.

Technical Specifications

- The device is designed and manufactured in accordance with ISO 21809-2 (14) and ISO 21809-1 standards.

- The possibility of testing coated laboratory samples according to the standard.

- It has a weight of one kilogram and a hardened indenter tip with a diameter of 15.8 mm for the ISO 21809-2 standard and a weight box and a hardened indenter tip with a diameter of 25 mm for the ISO 21809-1 standard.

- With a 1-meter graduated rod to release the indenter.

- It has a hardened base according to the standard.