In order to ensure the material is resistant to sour gas, a hydrogen permeability test or glycerin test is performed on the piece. This test, which is a conventional method for checking the amount of hydrogen diffused in metal parts, is designed based on the standard of Total and is used by many oil and gas companies as an acceptable method for checking resistance to hydrogen permeation.

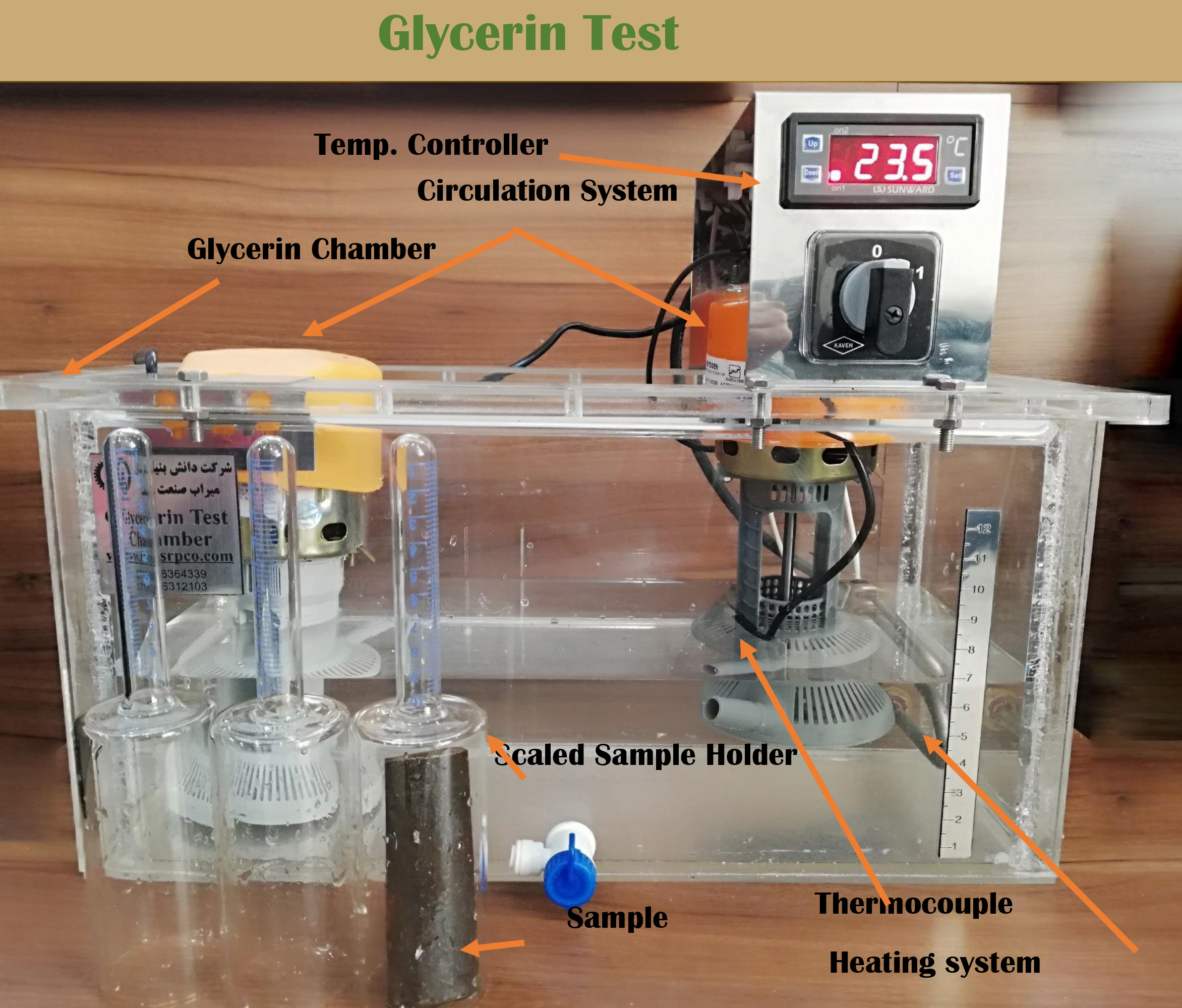

In the hydrogen permeability test, after the HIC test, the piece is removed from the test solution, immersed in ethanol, and then immediately dried by cool air. The samples are weighed by a scale with a minimum accuracy of 0.1 g and then enter a glass tube test which is graduated in the upper part and completely filled with glycerin. Four or six test pieces are placed in a bath containing glycerin. The test temperature in this test is 45 degrees Celsius and the test time is 72 hours. During the test, the hydrogen embryo penetrates through the cracks of the part to the outside of the part and gets trapped in the glass tube test. At the end of the test, the volume of hydrogen trapped in the cell test is reported in milliliters per 100 grams of the piece, and this amount of gas is the criterion for rejecting or accepting the piece based on the employer’s opinion.