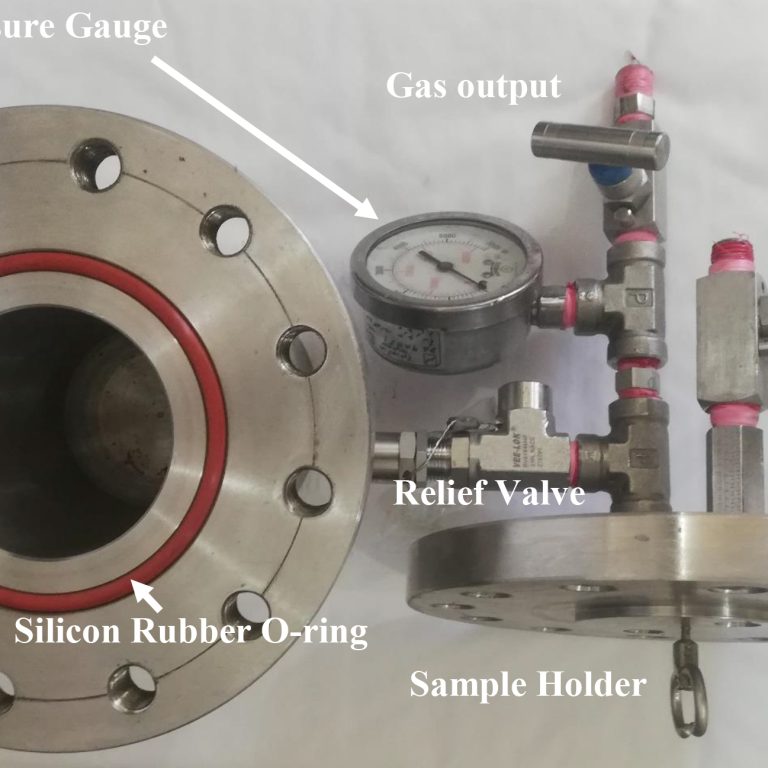

High pressure and high-temperature corrosion cell made by Mirab Sanat inc. has a volume of about 400 milliliters and provides the possibility of checking corrosion behavior in materials and equipment up to 3000 psi pressure and 150 degrees Celsius. This corrosion cell is completely made of stainless steel AISI 316 in one piece and without any welding. before the field test, it goes through many tests such as industrial radiography and pressurizing test, and relief valve calibration. In addition to stainless steel, it is also possible to make this vessel from other corrosion-resistant alloys such as Hastelloy or Inconel. This test cell has two places for corrosion coupons.

In addition to the above equipment, this set has an oven to place the chamber inside that to increase the temperature in a completely uniform way. The use of the oven provides the possibility of increasing the temperature without a high-temperature gradient and unwanted temperature increase during the test, and the fan in the oven creates high air circulation, which greatly helps the uniformity of the temperature during heating.

Technical specification of High-Pressure High Temperature Corrosion Cell:

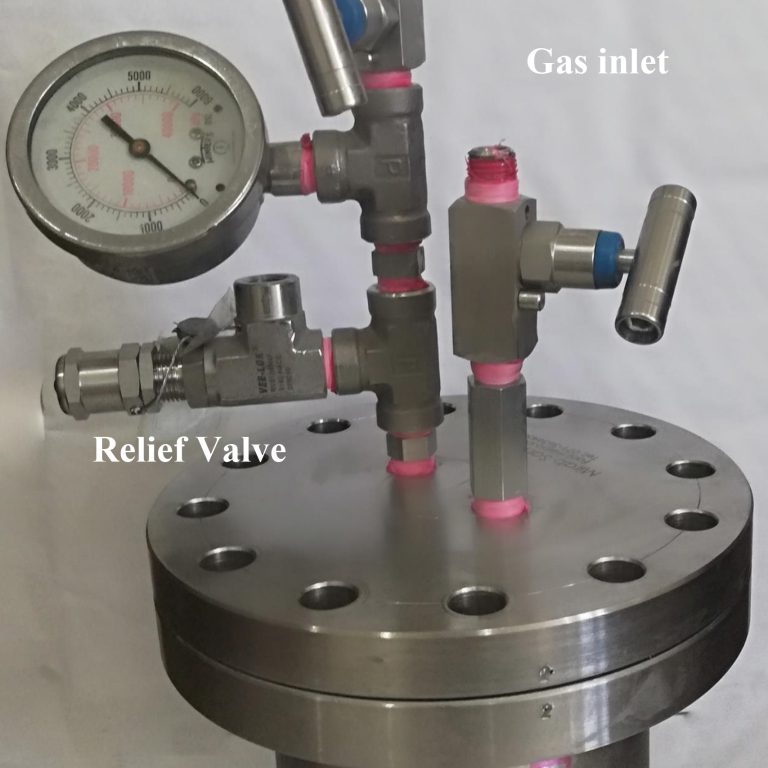

- Stainless steel gas inlet with ¼ NPT Male.

- Relief valve steel with the possibility of adjusting the pressure and gas discharge at the default pressure of 5000 psi.

- Pressure gauge with connections and steel body with the ability to display pressure up to 6000 psi.

- Stainless steel gas outlet with ¼ NPT male outlet.

- O-ring made of silicon rubber with the possibility of working up to 200 degrees Celsius.