The hydraulic hot press machine is used to produce flat sheets of adhesive granules or polyethylene granules or other polymer materials in order to make sheets, to perform coating tests regarding the standards such as ISO 21809-1/2. A hot press is a device that provides the possibility to pressurize the material while increasing the temperature. This equipment is widely used in various industries such as paint and coating industries, industries related to catalysts and chemicals, as well as materials research and development. One of the most important features of this device is the ability to control pressure, temperature and time with high accuracy and simultaneously.

The technical specifications of this device are:

- Hydraulic pressurizing system with the possibility of controlling the applied pressure up to 30 tons.

- Control system to control device variables digitally.

- The possibility of increasing the temperature up to 200 degrees Celsius in a completely controlled manner.

- It has a water circulation system with the possibility of quickly cooling the temperature of the mold after testing and adjusting the final temperature of the mold during cooling.

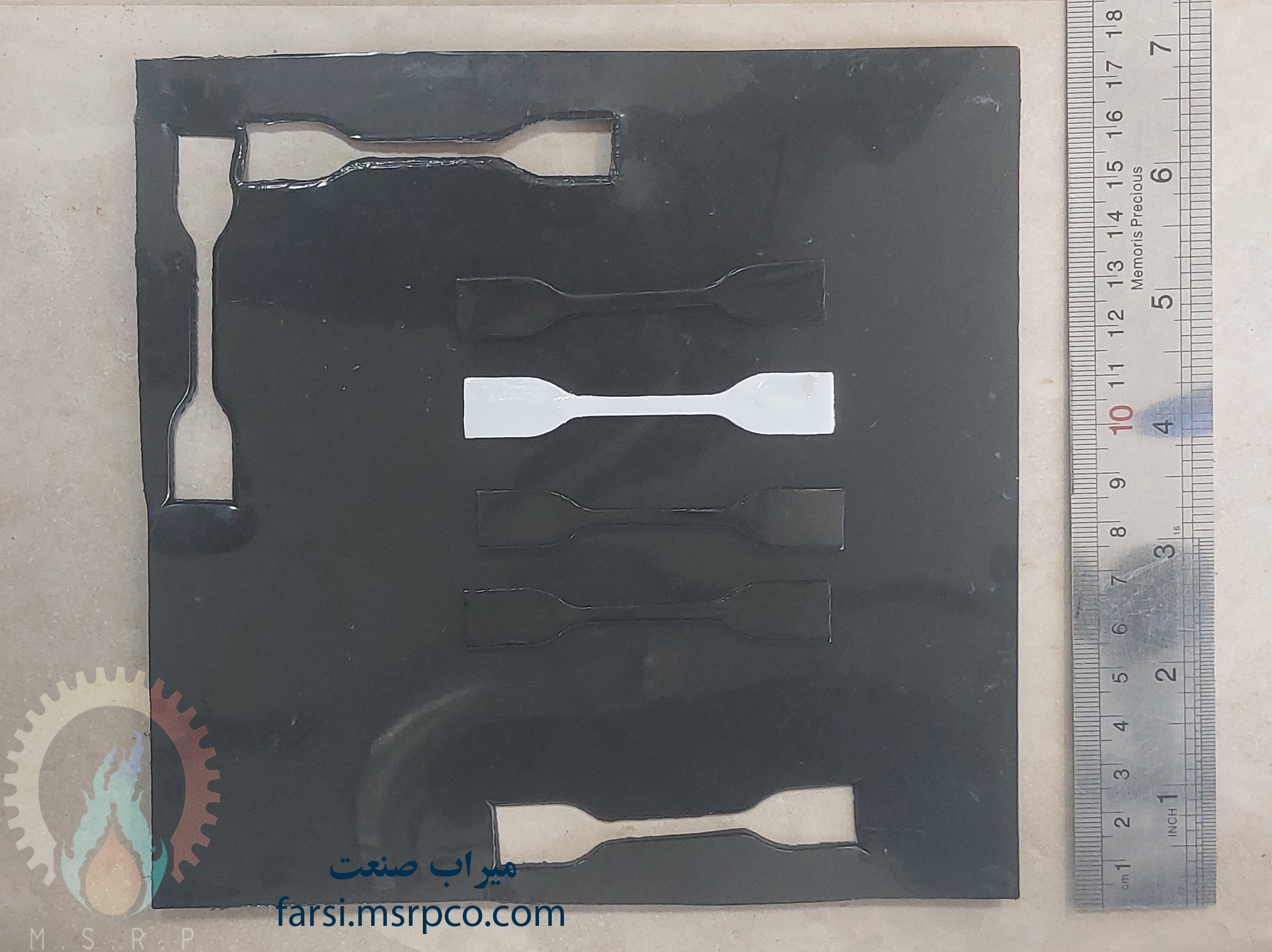

- The possibility of producing samples in different thicknesses with dimensions of 175 x 180 mm in a completely uniform way.

- It has a completely safe pressure control system in order to determine the amount of pressure applied during sample production.

Device components:

- The laboratory hot press machine has a hydraulic system to apply tension, a temperature control system to increase the temperature, and a water circulation system to cool the mold and sample. In addition, the machine has a digital control system to control temperature and time and the pressure gauge system is used to control the applied pressure.

- The produced laboratory samples have dimensions of 175 x 180 mm in different thicknesses (according to the thickness of the mold).