Mirab Sanat manufactures HIC testing apparatuses (hydrogen-induced cracking) to test and accurately determine the hydrogen-induced cracking resistance of metals. The hydrogen-induced cracking test is performed under the H2S fume hood as per NACE standards requirements. HIC testing is recommended to evaluate the resistance of pipeline and pressure vessel plate steels to hydrogen-induced cracking corrosion caused by hydrogen absorption from aqueous sulfide corrosion. hydrogen-induced cracking test apparatus meet the requirements of NACE Standard TM0284 and is suitable to test material as per requirements of NACE TM177.

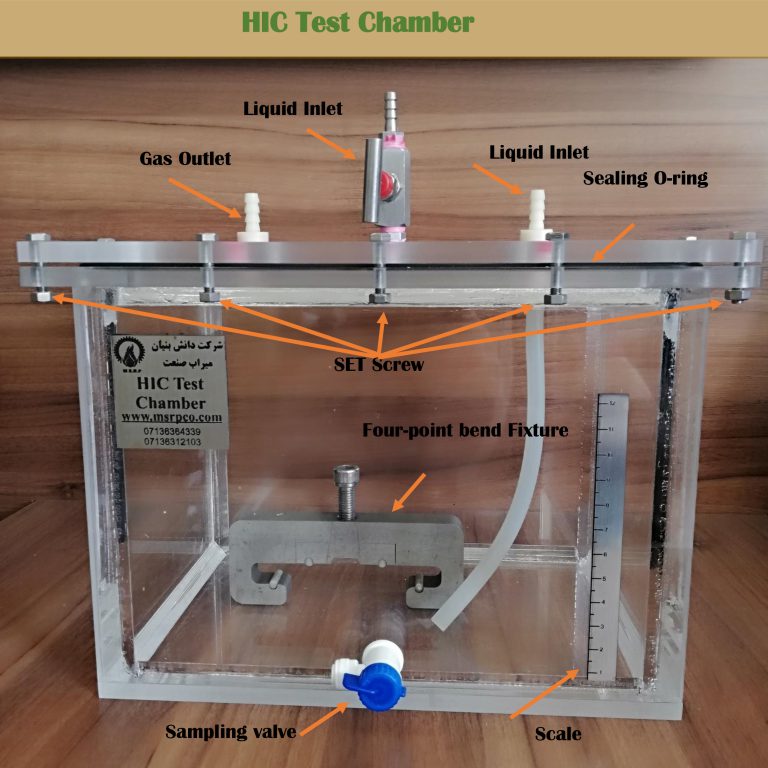

Specifications of the test chamber are as follows:

- Cubic body made of completely transparent acrylic Plexiglas with dimensions of 23 × 30 × 30 cm.

- Completely sealed against air and water.

- Has H2S inlet and outlet.

- Have a liquid drain valve inside the bottle.

- It has a fully sealed external chamber to trap and neutralize H2S.

- Due to its high volume, in addition to the HIC test in accordance with NACE TM0284, SCC, C-ring, and Bent Beam tests can be performed according to NACE TM-0177 2016 (methods B and C).