The H2S fume hood is designed and manufactured to work in environments with the H2S gas to perform the HIC and proof ring tests. This design allows the minimal removal of toxic gases such as H2S and makes a safe environment for operators. The H2S fume hood body is made of 3-layer PVC which is completely corrosion-resistant. Beyond this, the interior pipes and flow meter are made of stainless steel 316 which is resistant to the H2S gas. The hoods are equipped with the H2S sensor to detect toxic gases and are able to cut off gas leakage quickly in leakage accidents.

Technical specifications of H2S Fume Hood:

- PVC body with the approximate dimensions of 170 × 50 × 210 (L × W × H) (cm)

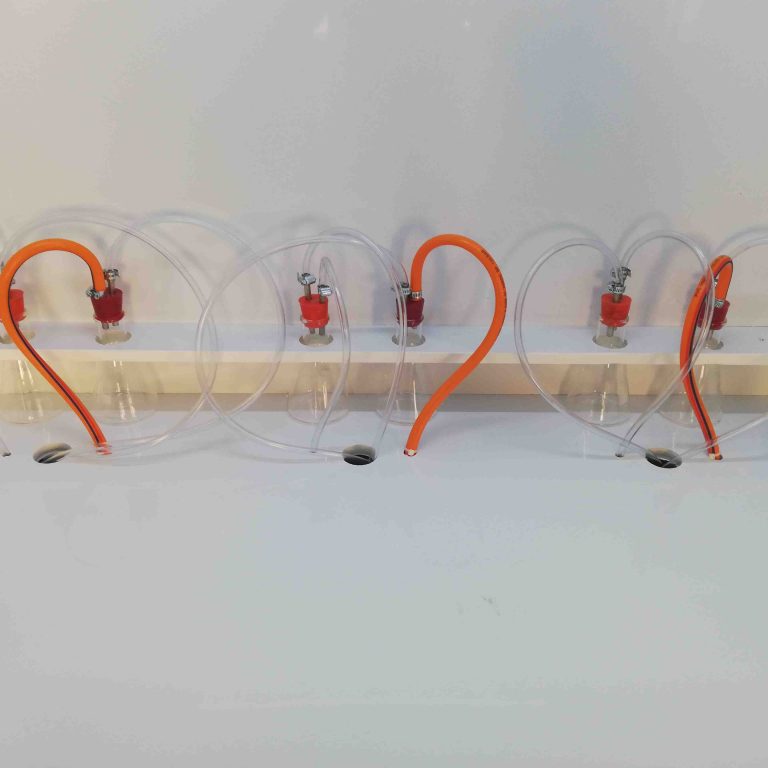

- Four stainless steel flowmeters to accurately determine the inlet gas flow.

- Gas trap system to uniform the gas flow.

- Maximum sealing to prevent toxic gases exit.

- Portable H2S sensor for alarm in leakage accidents.

- Remote hood monitor with cameras.

- Stainless steel piping for H2S and N2 gas injections and piping.

- A powerful air blower system and a specific internal design to exhaust the hood gas with the highest efficiency.

- With an H2S neutralizing system with the help of NaOH reservoirs.