The four-point bending test is a type of material mechanical properties test that can evaluate the sample’s resistance to bending. The principles governing the four-point bending test are the same as the principles of the three-point bending test, but in this test, two loading pins are used to apply force, and as a result, the bending test shows uniform tensile stress in a relatively large area of the sample. The purpose of the bending test in the HIC chamber is to investigate the corrosion performance of the component under static loading conditions (SCC test).

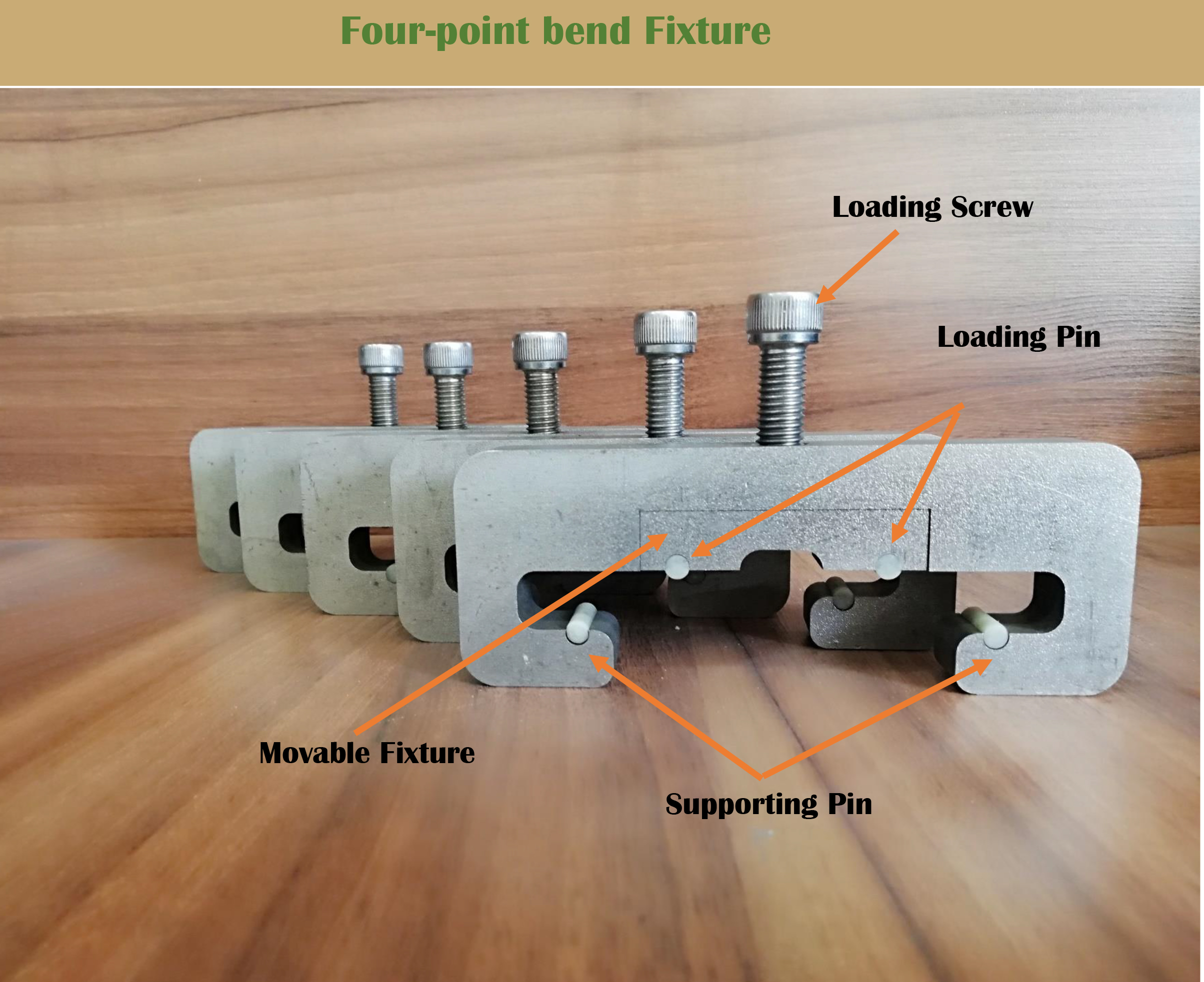

Mirab Sanat Company designs and manufactures the bending test holder in order to perform SCC tests in accordance with NACE TM0316, NACE MR0175, and ASTM G39 standards. 4-point bending testers are made of AISI 316 stainless steel with very high precision machining.

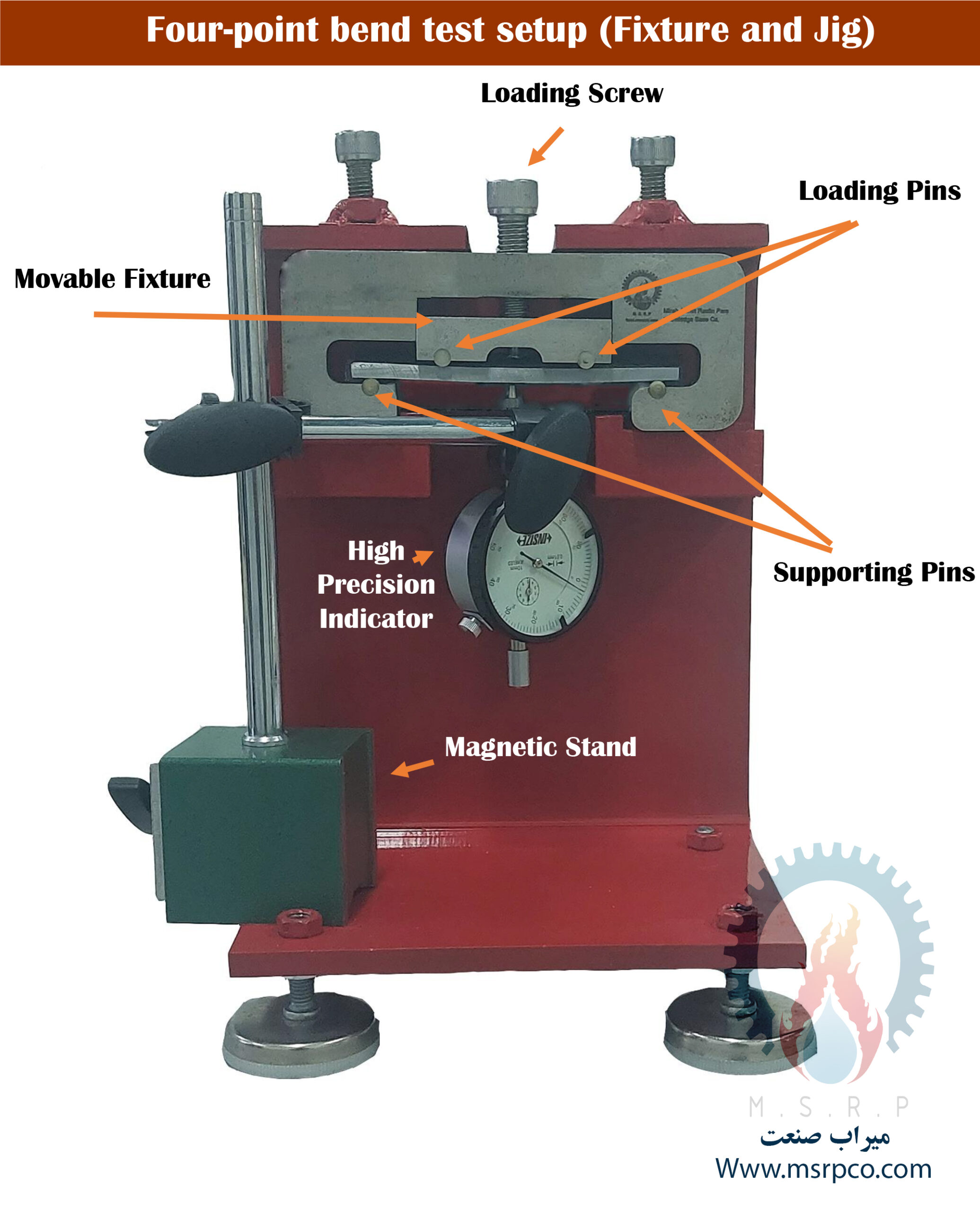

In order to determine the amount of stress applied to the piece, a special base and clock are used to determine the amount of deflection of the piece. This base is designed in such a way that the SCC 4-point bending test holder is placed inside it, and with the help of a very accurate indicator clock, the amount of strain applied to the part is calculated with an accuracy of 0.0025 mm. The amount of strain applied to the part is the criterion for determining the amount of stress applied to the part. After this, the piece will enter the HIC test chamber for sour gas tests, and the SCC test will be performed on it in its entirety.