Knowledge-based Mirab Sanat company, due to having a team of academic and industrial experts, declares its ability to manufacture laboratory test equipment’s to evaluate the corrosion and mechanical resistance of materials and equipment’s in harsh environments for oil and gas industries, universities, reference laboratories and innovative companies. It is worth noting that these products are designed in accordance with international standards as follows:

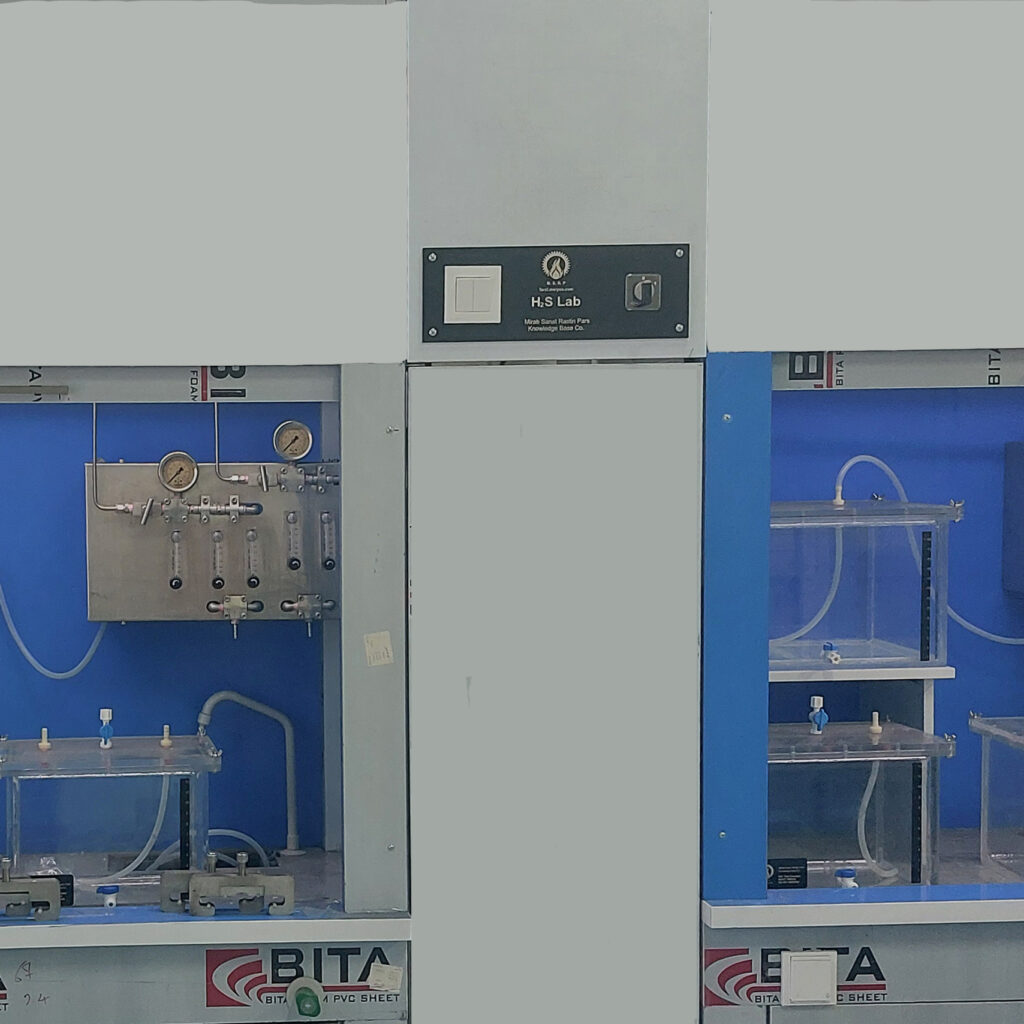

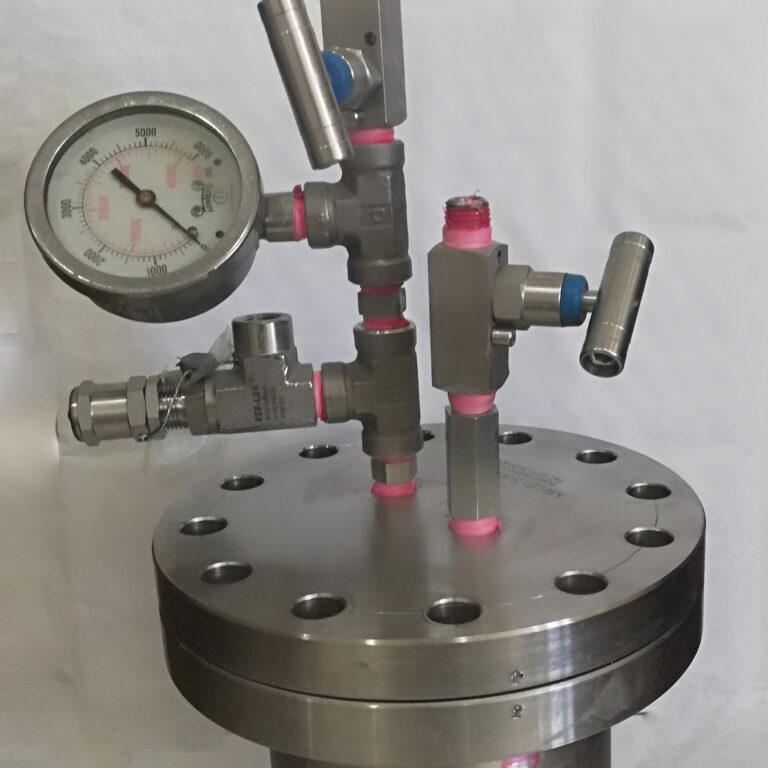

- Sour Gas test equipment’s: These products include the equipment’s and laboratory that makes the ability to test the materials in the sour gas environments regarding the NACE TM0177 and TM0284

- Inhibitor test equipment’s: These facilities include the equipment’s used to test the behavior of corrosion inhibitors in a turbulent environment. These test includes: wheel test ( NACE 1D182), rotating cage (ASTM G184), Jet Impingement test ( ASTM G208) and TOL

- General Corrosion Test equipment’s: These facilities are used to evaluate the general corrosion of devices and are as follow: HPHT Cell( high temperature- high pressure corrosion cell), Corrosion Cell, Copper corrosion test ( ASTM D130, ASTM D849 and ASTM D1838)and Rack test ( ASTM D2688).

Coating Incpection test: These equipment’s are used to test the mechanical and corrosion behavior of coatings ( specifically the FBE and Three layer PU coatings). These facilities include: Gouge resistance test ( NACE TM 0215- CZA Z245.20), CDT test (CSA Z245.20), Flexibility test ( ISO 21809 ), ESCR test ( ISO 21809), Indentation test (ISO 21809, EN 10289), Impact test ( ISO 21809, ASTM D 2794) and Hot press.

- Tracking and erosion test: this facility is used the test the insulation behavior of silicon parts in a very harsh environments regarding the IEC 60587