A corrosion coupon is a very inexpensive and common method for checking the corrosion rate in water, oil, and gas equipment. This disposable part provides high precision in determining the corrosion rate of the equipment for inspectors and operators. In addition, the use of coupons will be useful in recognizing the corrosion type of the equipment.

The use of corrosion coupons is a very cheap and common way to check the corrosion rate in water, oil and gas equipment, which provide the possibility of determining the corrosion rate on site with high accuracy. In addition, the use of couponing in order to determine the corrosion rate also provides the possibility of determining the type of corrosion mechanism.

Technical Specifications:

- Coupons are made without cold work and punching. Any effect of cold work on coupons is eliminated by heat treatment.

- Coupons are packed in anti-corrosion VCI bag packaging.

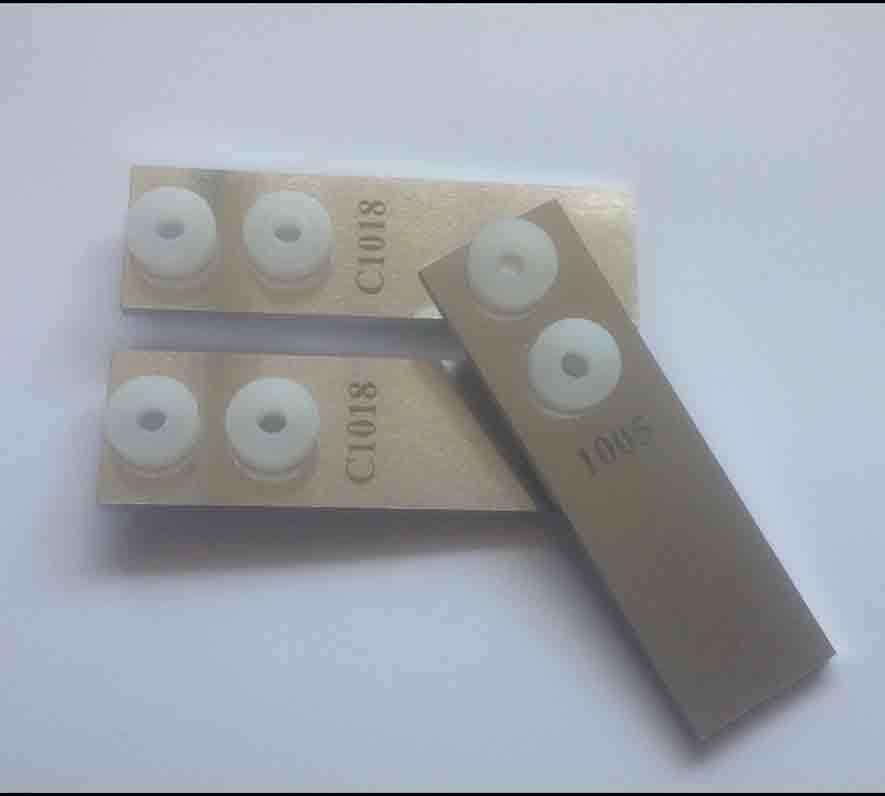

- All coupons are engraved with a material code and a unique 4-digit serial number.

- All coupons are weighted and packed to 4 decimal places.

- Coupons are prepared with uniform and requested roughness (multilevel roughness).

Applications:

- Simulation of corrosion behavior and determination of corrosion rate of materials.

- Investigating the corrosion behavior of materials in real pipe conditions.

- The possibility of testing in real environmental conditions.

Standards:

Coupons made by Mirab Sanat Industries are as follows:

Strip corrosion coupons

Disk and Flush Disk coupons

Scale corrosion coupons

Wheel Test Coupons

Strip corrosion coupons

The most common type of coupon is the strip corrosion coupon. These types of coupons have the highest contact levels compared to other coupons, and due to high contact levels, corrosion and weight loss mechanisms are more visible. Its dimensions typically as bellow:

Strip type( 3 inch):

76.2 x 22 x 3.2 mm (3 x 1 x 1/8 inches). Usually these coupons have two holes for mounting and the surface is in good contact for a corrosion test of about 3000 mm².

Strip type( 2 inch or ladder type):

50.8 x 22 x 3 mm (3 x 1 x 1/8 inches). Usually these coupons have two holes for mounting and the surface is in good contact for a corrosion test of about 2000 mm².

Strip type( 0.5 inch narrow type):

In cases where the pipe size do not let the common coupons the narrow type coupons are used. This coupons has the dimension of 76.2 x 12.7x 1.6 mm (3 x ½ x1/16 inches). c

جهت مشاهده این صفحه به زبان فارسی کلیک کنید

Disk and Flush Disk corrosion coupons

Disc Coupons

These coupons are used to simulate the movement of fluid in the wall of the pipes and their dimensions are ∅ 31.8 × 3.2 mm (1.25 × 1/8 inches). The effective contact surface in these coupons is 1700 mm² and in the middle of the hole for easy opening and closing. Multi-phase systems use multi-coupon systems to examine different phases.

Flush Disk corrosion coupons

industries uses this type of coupons in places that can not be used with regular coupons, and the interference generated in the flow of the line is unacceptable. Their standard dimensions are ∅ 31.8 × 3.2 mm (1.25 × 1/8 inches). The effective contact level in these coupons is 1500 mm².

جهت مشاهده این صفحه به زبان فارسی کلیک کنید

Scale corrosion coupons

These types of coupons are generally used to check the formation velocity and sediment type in pipes that are likely to form sediments. In general, they can also be used to determine the time required for pigging intervals. These coupons generally have two hole rows of six holes per row, each with a maximum diameter of 30% of the coupling width and a minimum of 0.5 mm.

جهت مشاهده این صفحه به زبان فارسی کلیک کنید

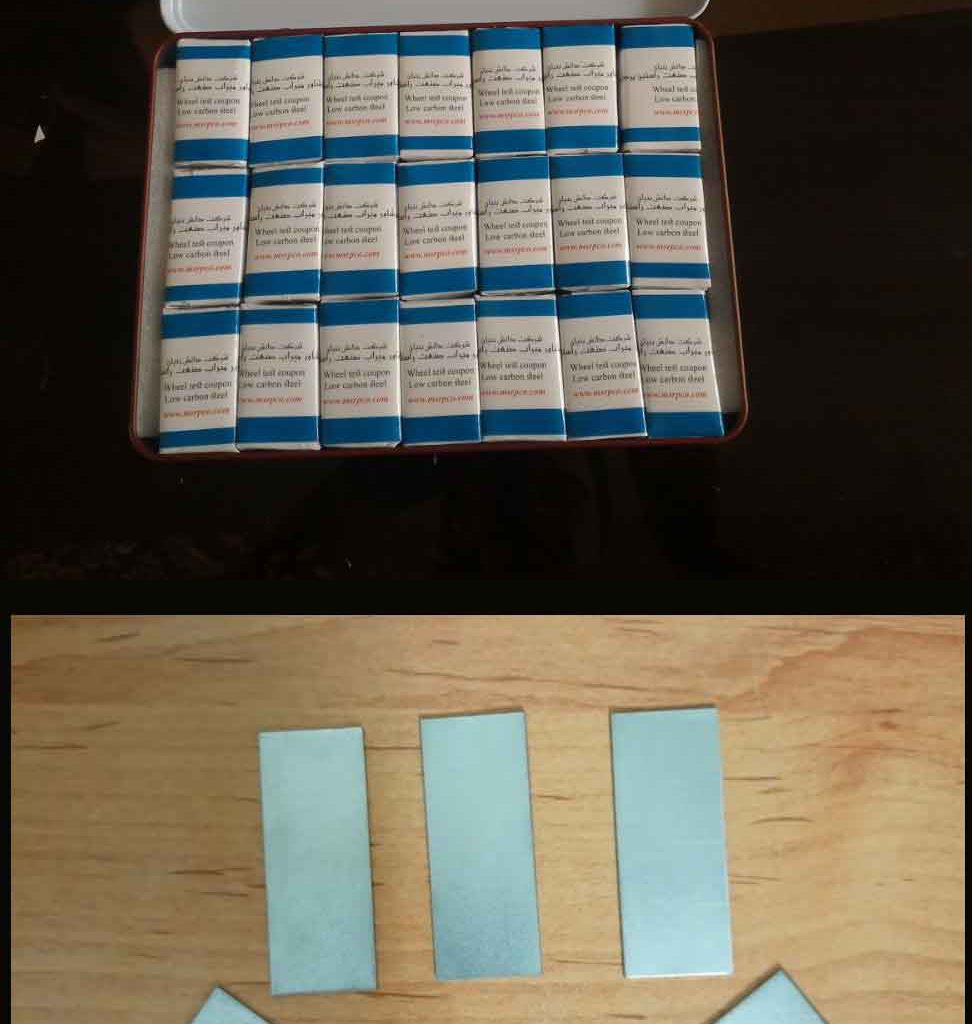

Wheel Test Coupons

This type of coupons are used in wheel test machine with the commandeered dimension of 75.4×12.5×0.127 mm (3 × ½ × 0.005 inch).

جهت مشاهده این صفحه به زبان فارسی کلیک کنید

Material type

Usually coupons are made of low-carbon steel, stainless steel, copper, bronze, brass and Inconel. Nevertheless, Mirab Industries declares its readiness to design and build coupons with other materials on the order of the buyer.

| Material type | Alloy | Similar name |

|---|---|---|

| Low carbon steel | AISI 1010 | ASTM A512/St12 |

| Low carbon steel | AISI 1018 | ASTM A512/St37 |

| Low carbon steel | API 5L | |

| Low carbon steel | ASTM A106 | |

| Low carbon steel | SAE 304 | 18/8 |

| Stainless steel | SAE 316 | 18/10 |

| Cupro-nickel, 90/10 | 90/10 | |

| Titanium | Ti-Al6-4V | |

| Aluminium | serries 6xxx and 2xxx |

Other coupon properties

Coupons, according to the buyer’s request, can have two roughness classes:

| Preparation technique | Standard feature | Surface roughness (Ra- µm) |

|---|---|---|

| As received | NACE No. 1/SSPC-SP5 | 0.5-1 |

| Blasted | NACE No. 1/SSPC-SP10 | 0.6-1.4 |

| Polished | NACE No. 1/SSPC-SP5 | 0.2-0.8 |

- All coupons have a laser hacked code and coupon code on the body.

- All coupons are annealed before cutting to eliminate the cold work .

- All coupons are produced by water and wire cut and are not punched.

- All coupons are carefully weighted and then packed up to four digits.

- All coupons are packed in double layer (VCI bag) and have one year expiration date.