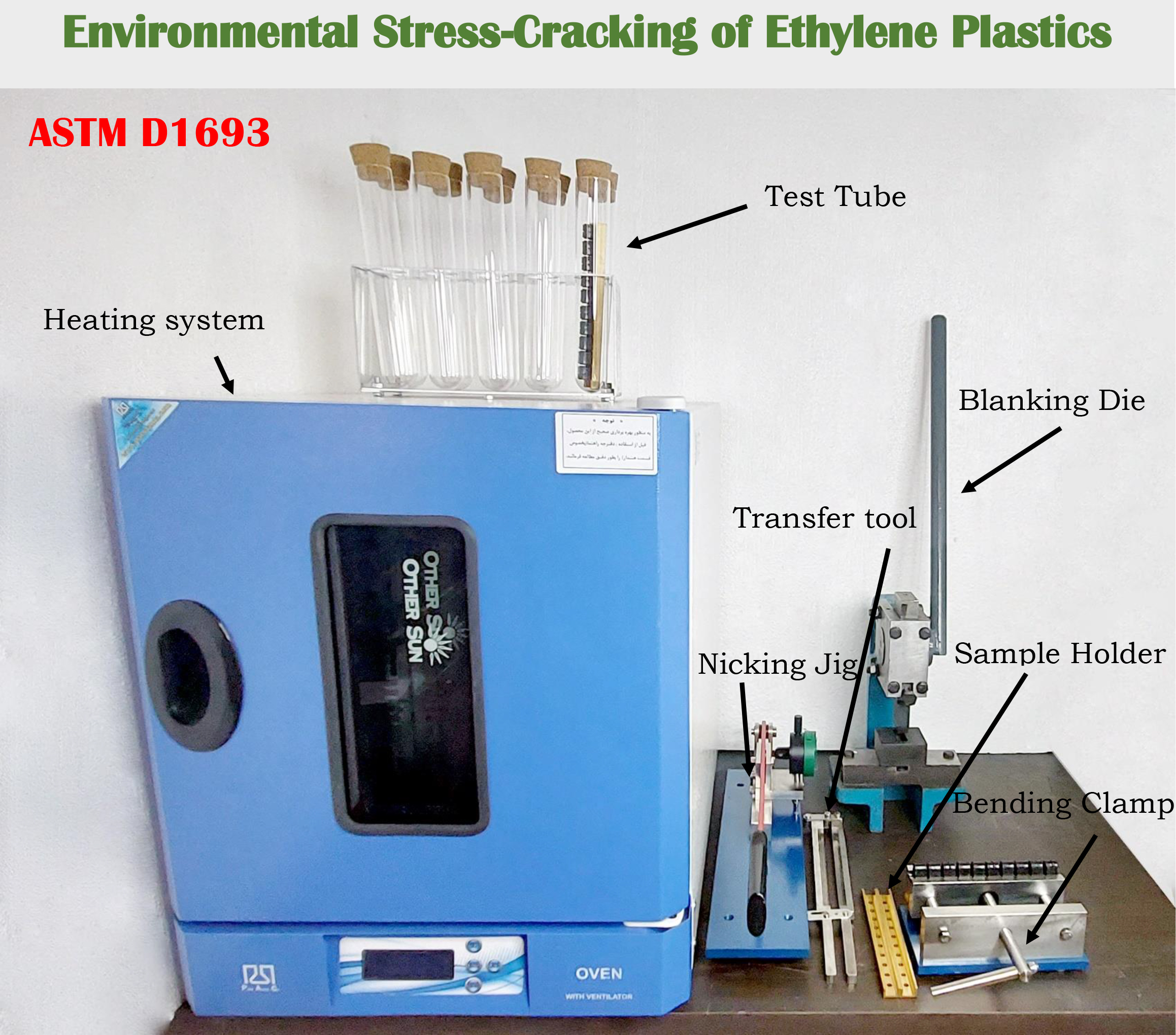

Environmental stress-cracking of ethylene plastics is used to check the stability of ethylene plastics in a corrosive environment and in the presence of stress cracks. Under certain stressful conditions and in the presence of environmental conditions such as the presence of fats, oil, wetting agents, washing agents, etc., ethylene-based plastics may tear. This test is designed to check the stability of these plastics in very corrosive conditions and is considered one of the important tests in checking the behavior of the coating on the pipes. This device is designed and built in accordance with ASTM D1693 standard and has the possibility of checking 10 samples simultaneously.

The environmental stress-crack test device has seven general parts as follows:

- Blanking die: a rectangular mold for cutting samples with dimensions of 2.5±38 mm per mm by 0.8±13 mm.

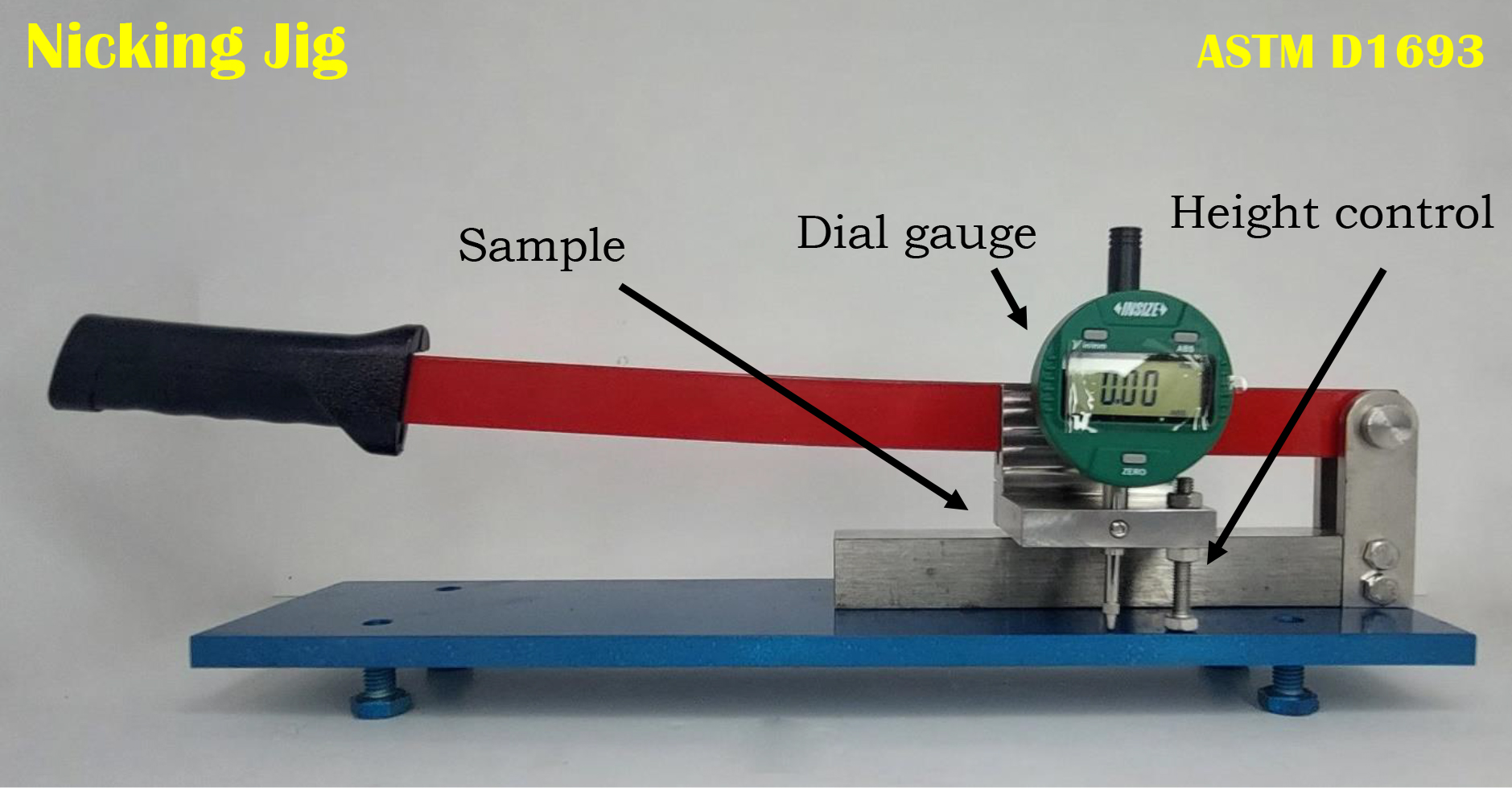

- Nicking Jig: To create a controlled defect in the samples according to the standard table, parallel to the long edges of the sample and in the center of the larger face.

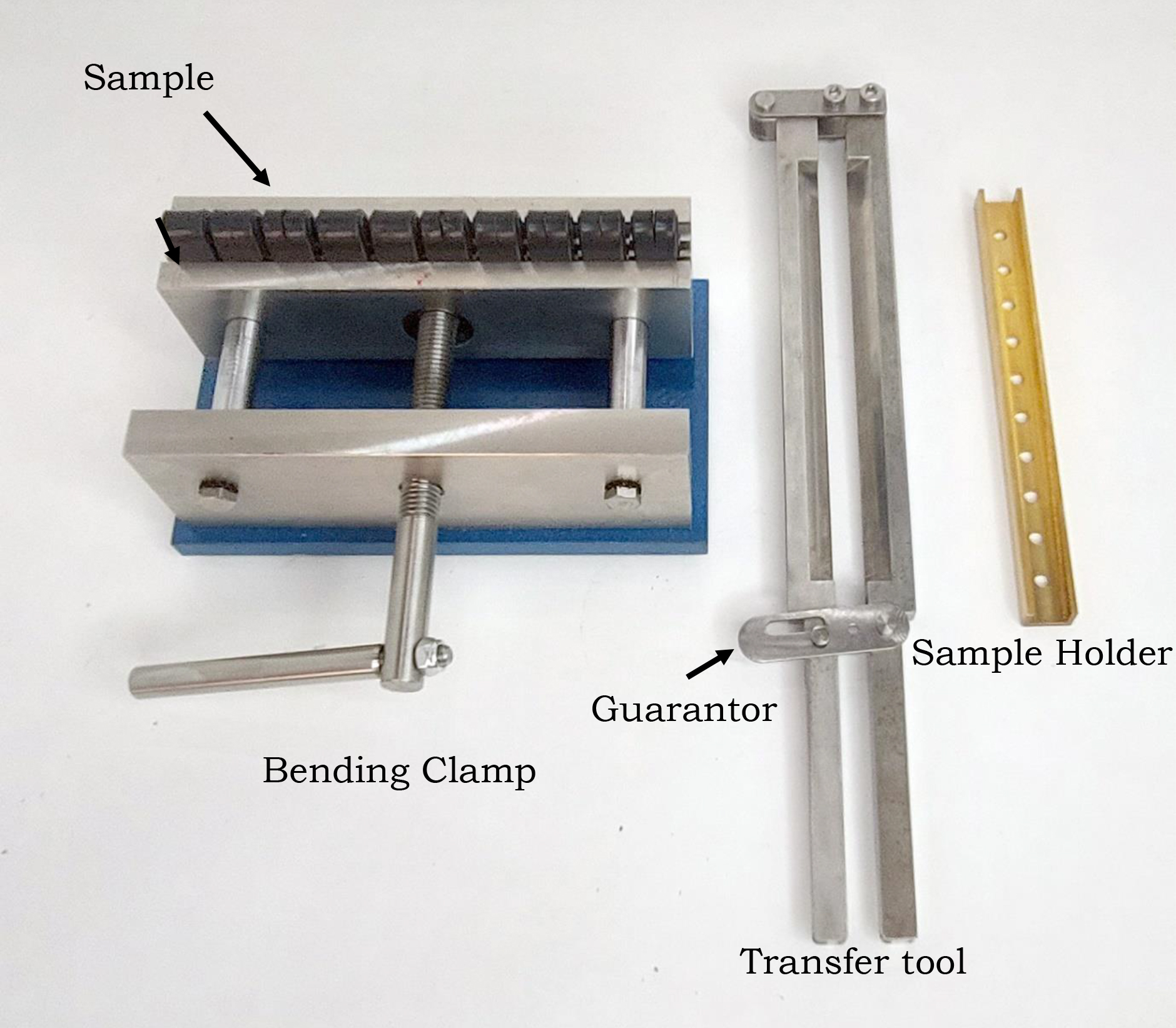

- Sample holder: This component, which is produced from hard or semi-hard brass, is used to place the sample in the test fluid environment.

- Test tubes: 200 mm long glass tubes with a minimum inner diameter (preferably) of 31.5 mm and a cork or rubber stopper.

- The heating system includes a standard chamber including a fan heating system with temperature control in the test range with an accuracy of ±0.5℃.

- Bending tool: to bend the test sample.