Access fittings are one of the most critical components of pipeline couponing. This equipment is designed to be permanently welded on the pipeline or tank. This equipment provides the possibility of installing the coupon with the help of a retriever without the need to cut off the gas or fluid flow. This equipment provides the possibility of safe coupon installing and removal, as well as prevents risks related to gas leakage from the line. The thickness of the part is such that it provides sufficient strength to work at pressures up to 6000 psi and a temperature limit of 205 to -40 degrees Celsius. If there is a sour gas environment, the material conforming to the NACE MR0175 standard is used. The outer part of the access fitting has a 3-inch thread in order to install the service valve when using the retractor, It is highly recommended to use a protective cover on top of the access fitting in order to protect the equipment and the thread of the access fitting. The protective cover is installed on the outer thread of the access fitting to protect the access fitting. The covers made in Mirab Sanat Inc. are of heavy duty type and are made of ASTM A105 carbon steel.

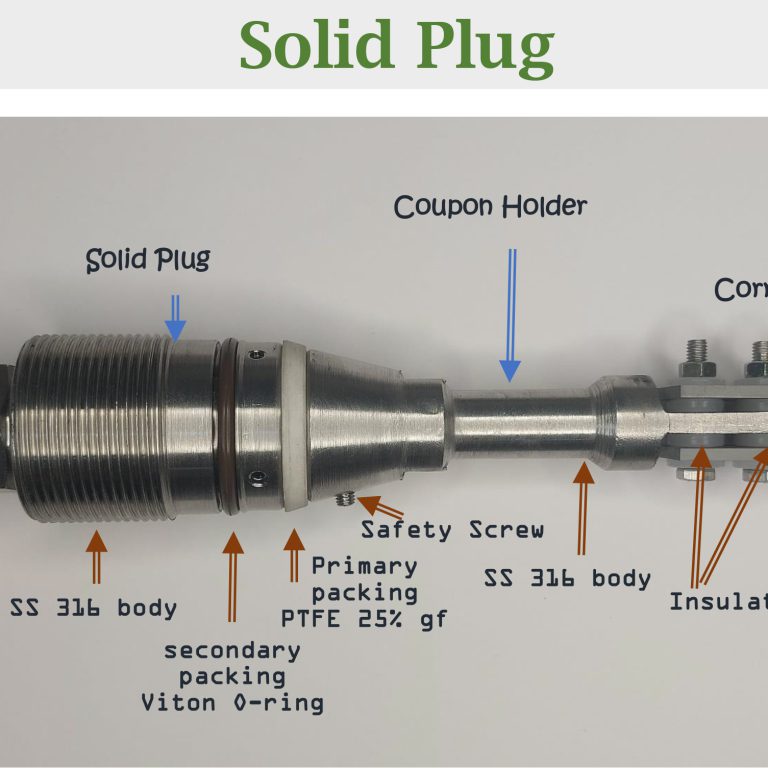

The solid plug is one of the internal components of the couponing system, which actually acts as a leak seal of the access fitting, to maintain the line pressure at the coupon installation location. On the other hand, this equipment is connected to the coupon holder and provides the possibility to enter and exit the coupon through the retriever. This equipment is used to store various types of coupon holders, probes and sampling equipment. Solid plugs made by Mirab Sanat company can withstand pressure up to 6000 psi or 400 bar, and for this reason, they provide the possibility of installing the coupon without interrupting the flow of the line. Each solid plug has the following 5 components:

- solid plug body made of SS316.

- Primary packing made of PTFE 25% glass fill.

- Viton O-ring: the O-ring on this equipment is actually considered as a secondary leak seal, which is responsible for sealing the leak after the primary packing. and it prevents fluid contact with its body threads

- solid plug nut: The nut on the solid plug allows the primary packing to remain in place when corrosion monitoring equipment is not on the line. And as a result of the solid plug, it remains completely airtight.

- set screw Pipe plug.