Mirab Sanat Rastin Pardis Company Abilities in the choice of materials and failure analysis are as follows:

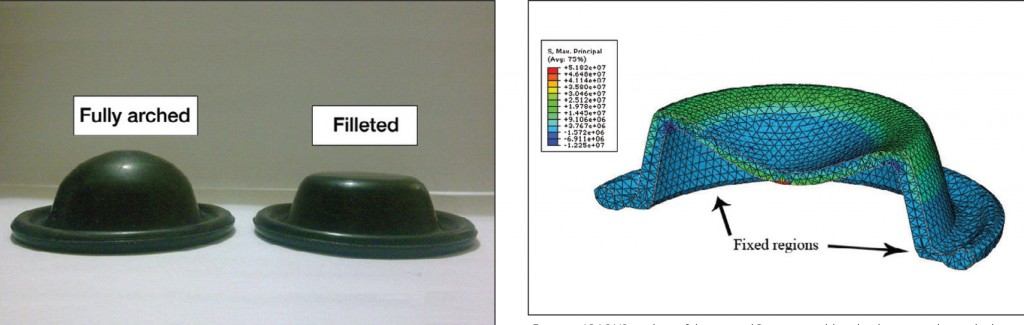

- Investigating the reason of early damage of parts as well as increasing the working life of instruments with the help of redesign, changing the materials or the type of loading.

- Increasing the wear resistance of the tools and instruments via coating, re-design or change the type of loading or materials.

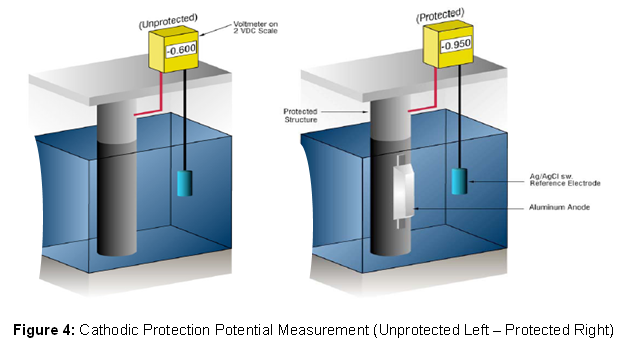

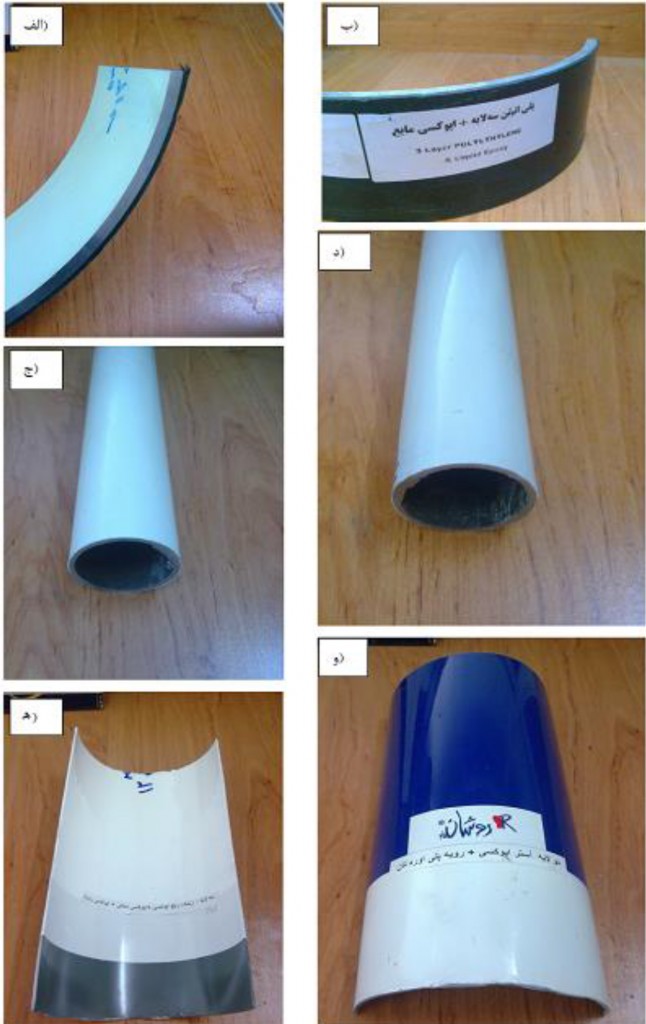

- Increase component life in corrosive environments with the inhibitor, cathodic protection, changing the materials or corrosive environments.

- Extending the life of components that are exposed to hot-corrosive environments with the coating or changing the materials.

- Reducing the vibration in tools according to the type of loading or redesign of the parts.