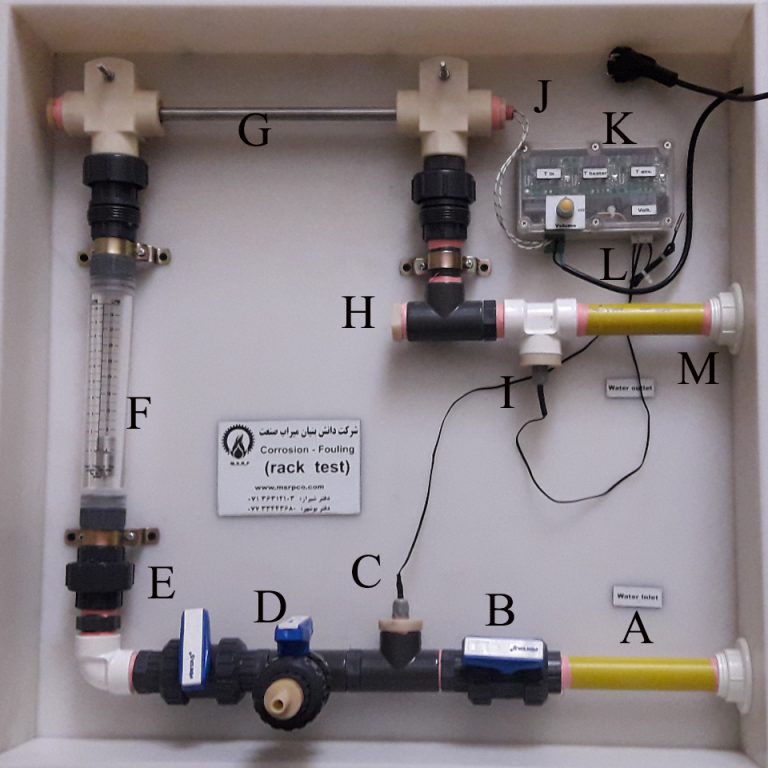

In the rack test machine, with the help of a simulated path, the corrosion rate is determined in a wide range of temperatures and pressures with the help of a weight loss corrosion coupon. This method is a very quick and economical way to determine the amount of corrosiveness in systems with obstructions or water transmission lines and chillers, which allows the user to check the performance of the passing fluid. This device is designed and manufactured in accordance with the ASTM D 2688 and ASTM D4778 standards.

Technical specifications of Rack Test:

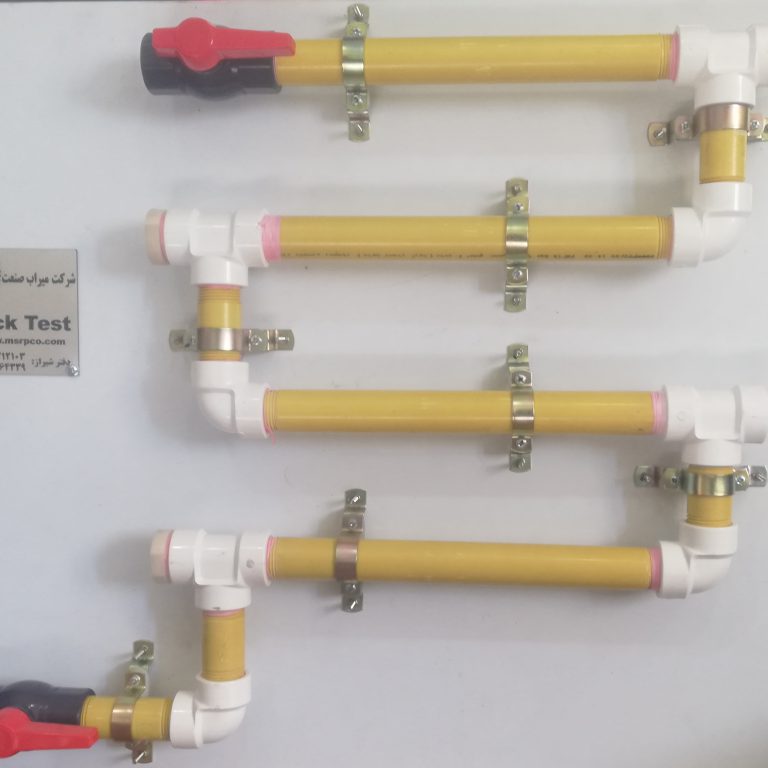

- PVC pipes and fittings with a pipe diameter of 1 inch

- Install 4 coupons instantly

- With a rotameter of 10 GPM

- Ability to work up to 60 ℃ and 8 bar pressure

- With Y-streamer to remove solid particles and appropriate ball valve